As of August 22, 2025, the Company's all-employee improvement initiative has yielded good results: in the past two years, employees have submitted over 6,000 "lean improvement proposals". These wisdom fruits from the front-line production and management positions have been continuously translated into fruitful outcomes of quality improvement and efficiency increase.

From the rise in welding automation rate to the improvement of inventory turnover efficiency; from the universal design of tooling to the promotion of molding die serialization, employee improvement proposals cover the Company's entire production chain and multiple management dimensions.

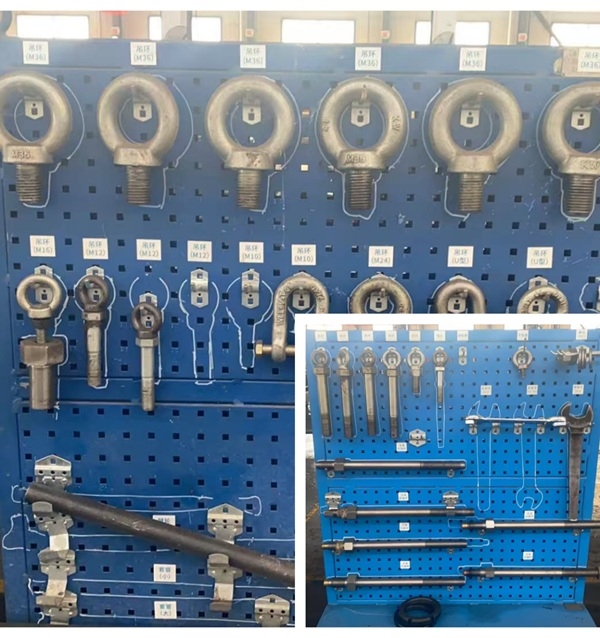

"Micro-innovation" unleashes "big benefits": The Steel Structure Division innovated the combined mold to achieve one-time processing and molding of sheet metal hat-shaped products, boosting efficiency by 2.4 times; The Locomotive Division independently developed rolling tooling, increasing product assembly efficiency by 25% and reducing labor intensity by 40%; The Ziyang CRRC Electric Locomotive Co., Ltd. implemented a torque wrench management system, with a 24-hour self-inspection rate of 100%; The Crankshaft Branch promoted tooling generalization, increasing management efficiency by 50% and raising the inventory turnover rate to 3 times... These practices vividly interpret the concept of "Build Premium Locomotives, Deliver Fine Work, Foster Excellent People".

"Lean in Mind&Action” is not only the lean cultural concept of CRRC Ziyang but also an institutionalized practice driving the company to achieve a "three-year leap" in lean management and a year-on-year increase in operating efficiency. To continuously stimulate the vitality of improvement, the Company has established a normalized incentive and evaluation mechanism:

Rankings are released monthly, with guidance provided to those at the bottom; excellence is recognized and rewarded quarterly; and the "Top 10 Improvement Proposals" are announced annually. This has truly fostered a positive cycle where "those who drive improvements benefit, and those who fall behind strive to advance."

Today, a company-wide atmosphere of continuous improvement has become prevalent. CRRC Ziyang will continue to deepen lean management, refine incentive mechanisms, and drive more "micro-innovations" to yield "efficiency results," steadfastly moving toward becoming a more advanced "lean enterprise."