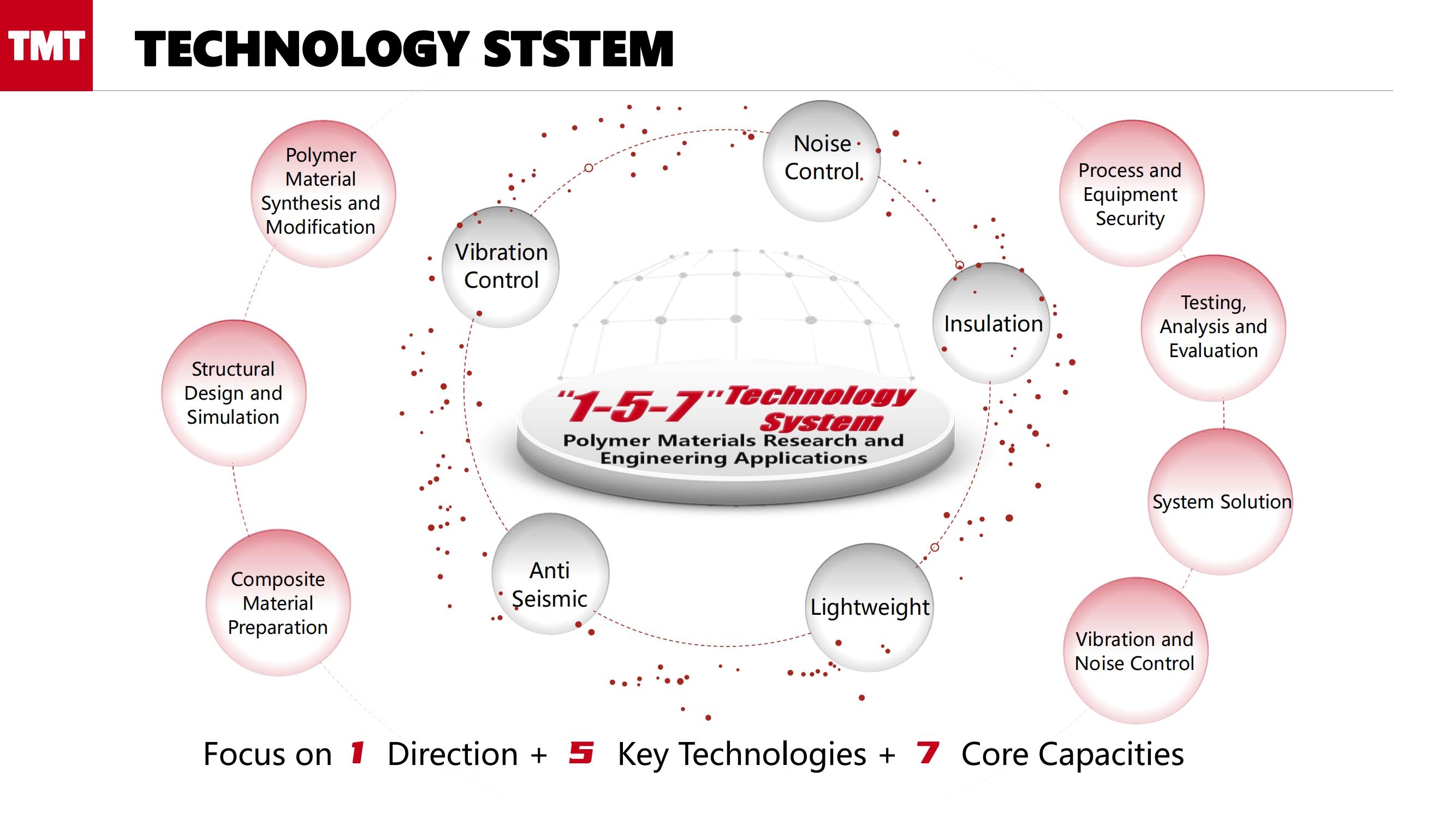

“1” Development Direction:

With the development direction of “research and engineering of polymer materials”, a system of research and development, manufacturing, sales and service of related products in rail transit, wind power generation, automobile, industry& engineering, new materials and other fields has been formed.

“5” Major Technologies:

The 5-key-technology, a significant breakthrough that combines new materials and product structures, includes vibration reduction technology, noise reduction technology, lightweight technology, flame retardant(Anti-Seismic) technology, and insulation technology.

“7” Core Competencies:

1. Synthesis andmodification ability of polymer materials:

Synthesis of polyimide, polyamide imide, aramid, high-temperature-resistant polyamide, organosilicone, polyurethane, functionally-unsaturated polyester, epoxy resin and other resins; carbon black (silica) in-situ grafting modified rubber, modification of shock absorption/vibration materials, flame retardant modification of polymer materials, heat resistance modification of polymer materials, interface modification of polymer materials, etc.

2. Structural design and simulation ability:

Optimization design of polymer composite material structures, fatigue lifespan prediction simulation, rubber and plastic molding process simulation, dynamic simulation of rail transit vehicle-rail line-bridge (tunnel) coupling system, dynamic simulation of automobile and wind turbine systems, noise and vibration simulation, fluid-thermal structure coupling analysis, wind turbine blade aerodynamic analysis, and bridge structure analysis, etc

3. Composite material preparation ability:

Advanced composite material molding technologies such as vacuum injection technology, HP-RTM technology, winding technology, pultrusion technology, and autoclave technology, etc

4. Vibration and noise control ability:

Rail Transit: Vibration and noise testing, control and program evaluation of the “vehicle-rail line-bridge/tunnel” system;

Automobile: Research and development of vibration reduction performance evaluation, and vehicle installation and calibration of powertrain mounts and cab mounts for the entire vehicle; research and development of vehicle acoustic package and acoustic performance evaluation; Vibration and noise testing and control in wind power, shipbuilding, aviation and other fields.

5. Testing, analysis and evaluation ability:

Professional testing and analysis of polymer material products and components; Qualifications: CNAS, CMA, DNV • GL, CCS

6. System solution ability:

Rail transit: Integration of vehicle-rail line-bridge vibration and noise reduction systems, covering rail vehicle suspension systems, rail line vibration reduction system, and bridge vibration reduction systems;

Automobile vibration reduction: Integration of active/semi-active damping systems;

Large scale equipment field: Integration of thermal insulation and cooling treatment systems.

7. Technology and equipment support ability:

Large scaletechnology equipment: large tonnage vulcanizing machine, K4/K6 internal mixing system, automatic polishing robot, automatic detection line;

Tooling mold design: injection type high-pressure multi-cavity mold, automatic resin injection;

Technology: ultra-high pressure precision vulcanization, technology cloud, RTMAVIP;

Digitization: CAPP, MES, digital factory.