On January 9, the National Railway System Commendation Conference for Advanced Collectives and Advanced Individuals was held in Beijing. Two collectives and four individuals from CRRC were awarded the titles of “Advanced Collective of the National Railway System” and “Advanced Individual of the National Railway System.” Wang An, Deputy Secretary of the Party Committee of CRRC Group, attended the conference. CRRC employee Yu Dalian delivered remarks at the meeting as a representative of the award recipients.

Following the conference, Song Xiude, Secretary of the Party Leadership Group and Administrator of the National Railway Administration, chaired a symposium and held face-to-face discussions with individual award recipients, learning about their work and listening to their views and suggestions on the development of the railway sector. Yao Zhihui, a CRRC employee, shared her reflections on reporting her frontline work experience to President Xi Jinping as a representative of high-speed railway workers.

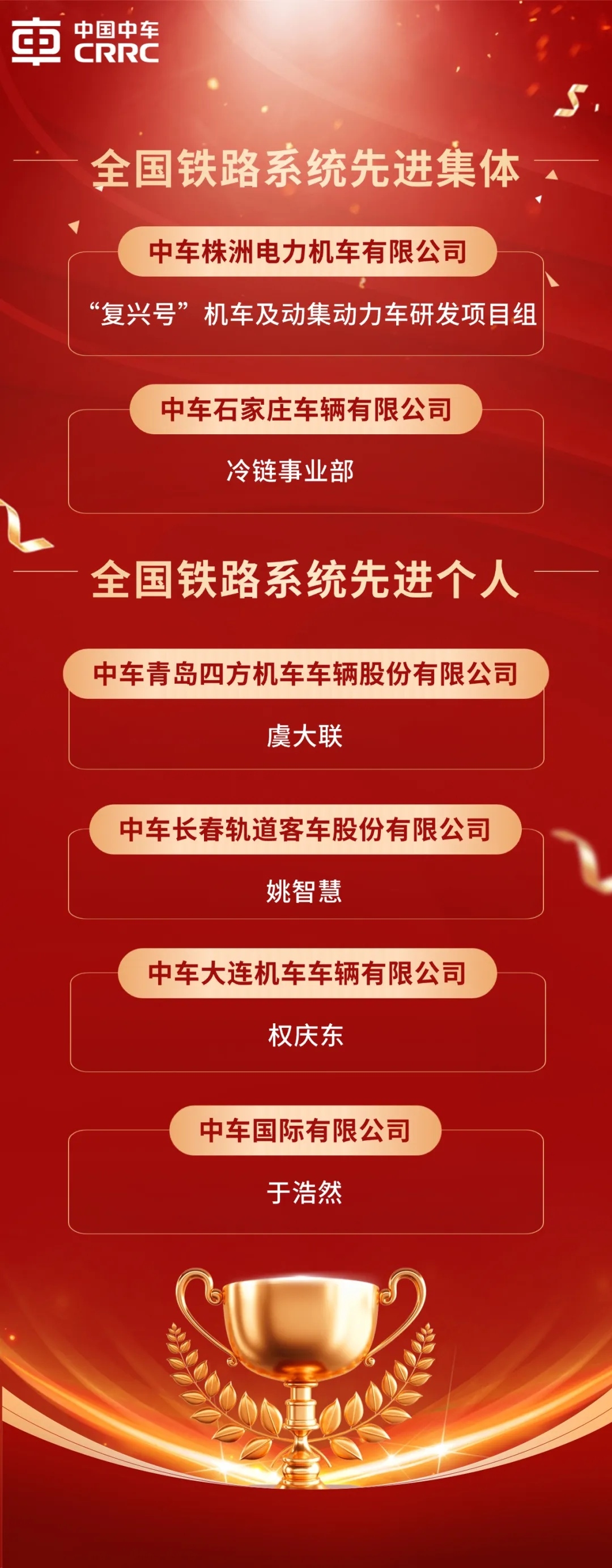

Awarded Collectives

CRRC Zhuzhou Locomotive Co., Ltd. - “Fuxing” Locomotive and Power Car R&D Project Team

The project team has focused on major national priorities such as the Sichuan–Tibet Railway and the dual-carbon goals, aligned with the national strategies of building China into a transportation powerhouse and advancing the Belt and Road Initiative. Focusing on challenging operation environments and next-generation rail technologies, the team developed centralized-power EMUs operating at 160 km/h and 200 km/h, six-axle and eight-axle locomotives, as well as hybrid and dual-power models. These products support complex routes such as plateaus and long-distance corridors, expand low-carbon traction solutions, and strengthen China’s capability to independently develop high-end rail equipment.

CRRC Shijiazhuang Co., Ltd. - Cold Chain Business Division

The Cold Chain Business Division has remained focused on the high-end cold chain logistics equipment sector, adhering to technological self-reliance and self-strengthening. The division achieved key breakthroughs in domestically developed refrigeration units and phase-change cold-storage technologies for railway logistics. Its equipment has been deployed on major international transport routes, including the China–Laos Railway, carrying over 1,000 containers of high-value fresh goods, supporting both cross-border trade efficiency and reliable cold-chain transport.

Awarded Individuals

Yu Dalian (Qingdao CRRC Sifang Rolling Stock Co., Ltd.)

As the Chief R&D Engineer at the Maglev R&D Center, with nearly 40 years in rail running-gear R&D, Yu led landmark bogie innovations including the SW-160 and SW-220K, supported the CRH2 and CRH380A EMUs reaching 486.1 km/h, and contributed to the rollout of the 600 km/h high-speed maglev train, strengthening China’s capabilities in frontier rail technologies.

Yao Zhihui (CRRC Changchun Railway Vehicles Co., Ltd.)

As a frontline vehicle electrician, Yao has led nearly 30 key process breakthroughs across 10+ train models, laid about 35 million meters of cabling, and supported the delivery of over 6,100 high-speed rail vehicles, while advancing digital upgrades on the production line and sharing hands-on manufacturing experience with the public.

Quan Qingdong (CRRC Dalian Co., Ltd.)

Quan Qingdong is a senior skilled expert who has been dedicated to frontline after-sales service for 25 years. He has continuously worked on plateau railways such as the Qinghai–Tibet and Lalin lines, repeatedly traversing sections above 4,000 meters in altitude to conduct on-site data collection, resolving hundreds of high-altitude technical challenges, introducing cost-saving on-vehicle inspection solutions, and training 1,000+ maintenance professionals to strengthen frontline operational capability.

Yu Haoran (CRRC International Co., Ltd.)

As the General Manager of CRRC International Latin America and Project Director of the Guadalajara project in Mexico, Yu led the approval of 1,000+ technical documents with zero errors, led the development of a “dual-cycle” risk prevention and control system and maintained a zero-liability safety record, setting a benchmark for risk-controlled delivery of complex overseas rail projects.