During the National Day holiday, the CCTV News Channel visited CRRC, offering viewers an up-close look at the technology and development behind China’s high-speed rail.

“Train Town” Reflects the Rapid Rise of China’s Rail-Transit Industry

From steam locomotives to high-speed EMUs and maglev trains, China’s rail-transit equipment has leapt across multiple generations. A single EMU now contains more than 40,000 components and involves suppliers from over 20 provinces—one train connecting an entire supply chain.

CCTV reporter Gu Junling noted that China’s first domestically produced steam locomotive, built in 1952, ended the nation’s inability to manufacture locomotives; the 380A EMU reached a test speed of 486.1 km/h in 2010; and the world’s first 600 km/h high-speed maglev train stands alongside them. Together, the three vehicles create a “time tunnel” that links China’s past, present, and future in rail equipment.

The newest milestone of this timeline points to Qingdao—home to the country’s densely clustered “Train Town.” More than 220 rail-transit suppliers operate here, producing high-speed EMUs, metro trains, and tram products. China’s first Fuxing EMU and the world’s first 600 km/h maglev both rolled off production lines here. The area also hosts China’s first national technology innovation center for rail transportation. Driven by a leading enterprise, the industrial cluster connects more than 6,000 upstream and downstream SMEs. The model integrates high-speed rail, metro, and light-rail product families to form a comprehensive and unique rail-transit ecosystem.

According to Wang Zhen, Executive Deputy Director of the Qingdao Rail Transit Industry Demonstration Zone, the zone uses its leading enterprises to map and coordinate key upstream and downstream suppliers, and actively targets suppliers not yet located in Qingdao, especially those with annual supply volumes above RMB 10 million. From January to August, the zone’s rail-transit equipment output reached RMB 31.6 billion, up 36% year-on-year.

Beyond Qingdao, China has developed characteristic rail-transit clusters in Zhuzhou, Chengdu, Nanjing and other regions. The country now hosts 44,600 rail-equipment-related enterprises—maintaining the world’s largest, most complete, and most dynamic rail-transit industry. The sector is shifting from “expanding scale” to “creating value,” working toward a world-class rail-equipment manufacturing base.

Inside the Home of High-Speed Rail: Exploring Rail-Equipment Technology

High-speed rail—one of China’s signature achievements in modernization—has progressed from following global leaders to becoming a global leader itself. China has completed the full cycle from technology import and adaptation to full-scale independent innovation.

During the holiday, China’s first high-speed-rail-themed interactive science museum opened in Qingdao. Designed to help the public explore the “secrets of speed,” the venue blends cutting-edge technology with the spirit of Chinese manufacturing. Children gathered around dozens of hands-on exhibits, experiencing how high-speed trains are designed, welded, assembled, and tested. A highly realistic rail-transit sandbox showing trains running through mountains drew crowds of young visitors. People could also take on the role of high-speed rail engineers and participate in the full R&D process. CRRC also opened its manufacturing workshops to the public. In a large assembly hall, train cars were being assembled in real time. Craftsmen demonstrated precision hand-skills—such as cutting a 0.2-mm steel strip into shape by hand with tolerances within 0.02 mm—drawing admiration from visitors.

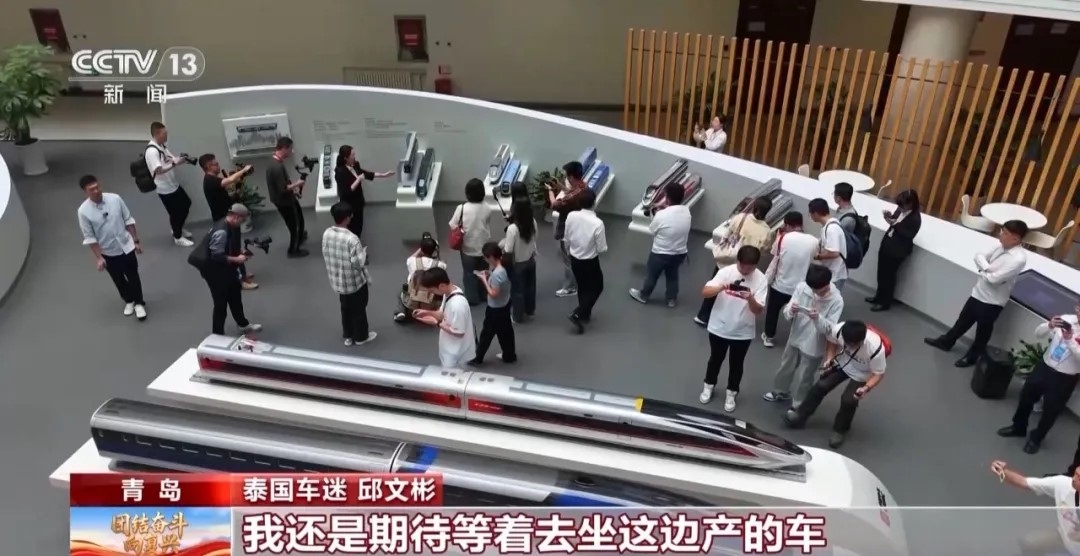

Rail fans from China and abroad also travelled to see their “dream trains.”

Thai rail fan Qiu Wenbin:“ I am excited to see high-speed trains and maglev trains being built and looked forward to riding CRRC-made trains in the future.”

CRRC engineer Xu Deyang, who works on the Jakarta-Bandung High-Speed Railway, shared that similar science outreach events are held overseas as well. Hundreds of Indonesian visitors recently attended one, showing strong interest in China’s rail-transit technology.

Master Craftsman: Strengthening the “Knees” of High-Speed Trains

The rapid rise of China’s rail-transit industry is inseparable from the dedication of countless front-line workers. One of them is Guan Yihui, who has worked at Qingdao Sifang for 34 years and was awarded the national title of “Great Country Craftsman” last month.

When Guan first joined the company, equipment was limited and many components required manual polishing. Later, the company purchased imported machining equipment, but the fully English interface was a challenge for him as a vocational-school graduate.

“Each parameter and command was in a foreign language, so I had to study every one of them thoroughly—understand it, master it, and apply it correctly in our machining work,” Guan recalled.

As China’s high-speed rail network expanded, Guan shifted his focus to solving vibration and stability issues—specifically, improving the performance of the axle box, a core component located under the train body.

“The axle box is like the knees of a human body—it carries the load and transfers power. It bears the weight of the entire train, and the smooth, stable ride you feel on a high-speed train relies heavily on this component,” he explained.

Through hundreds of trials, Guan and his team built a world-leading flexible production line for axle boxes. Their work pushed manufacturing precision to new levels, achieving a mass-production pass rate of over 99% and earning more than twenty patents. CRRC Sifang fully supports his innovations, establishing an innovation studio for him in 2022 to focus on tackling technical bottlenecks, developing talent, and passing on craftsmanship.

“With digital and intelligent systems improving, one person can now manage an entire production line, and a few people can run a full workshop,” Guan said. “Our output and quality keep rising.”

Today, the company not only manufactures high-speed EMUs but also produces metro trains, maglev trains, hydrogen-energy trains, and other types of rail-transit vehicles.

“My growth has been inseparable from the growth of China’s high-speed rail,” Guan said. “I hope to contribute even more to advancing our rail-transit industry.”